Analytics

Leverage industrial AI and machine learning to help improve operations and reliability and reduce costs

What is analytics software?

Analytics software mines historical data and employs advanced analytics and modeling techniques to determine patterns and trends that can predict future scenarios. This helps identify risks, opportunities, and outcomes. It is essential to any digital, data-driven strategy.

Benefits of analytics software

GE Digital’s Analytics Solutions

GE Digital’s analytics solutions combine deep domain expertise with applied analytics and digital twin technology. Predictive maintenance tools rapidly identify problems, discover root causes, and optimize operations in a variety of industrial settings.

Enable operational work processes with a scalable suite of solutions

Asset Performance Management

Our Asset Performance Management (APM) software is a suite of tools using predictive maintenance technologies to monitor assets to reduce downtime, boost availability, and increase reliability. By detecting problems early, predictive maintenance software turns costly emergency or unplanned shutdowns into planned, scheduled downtime, saving time and money.

EXPLORE ASST PERFOEMANCE MANAGEMENTPredict and prevent equipment failures

SmartSignal

SmartSignal enables a smart maintenance strategy by helping to detect, diagnose, forecast, and prevent emerging equipment failures on hundreds of common industrial assets. Powered by unique Digital Twin analytics, SmartSignal’s early detection and time-to-action forecasting drive improved reliability with maximum operations and maintenance efficiency, making smart maintenance easy and cost-effective.

EXPLORE SMARTSIGNAL

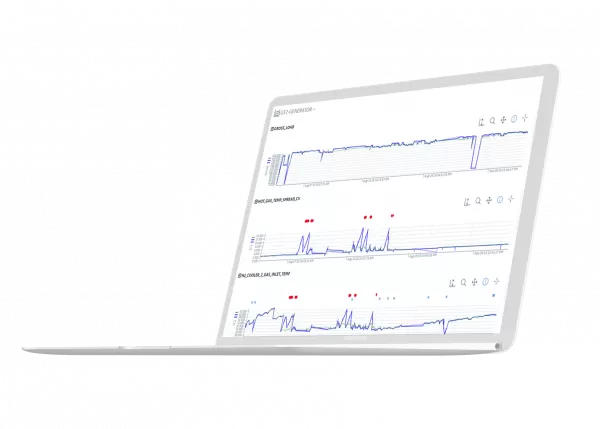

Process Analytics for Oil & Gas and Petrochemical

TrendMiner is an intuitive web-based industrial process analytics application to perform visualization of large amounts of sensor-generated time-series and contextualized data. The solution enables process optimization through its enhanced functionality for process monitoring, troubleshooting, and embedded problem-solving capabilities.

EXPLORE PROCESS ANALYTICSImprove asset and process performance with a Process Digital Twin

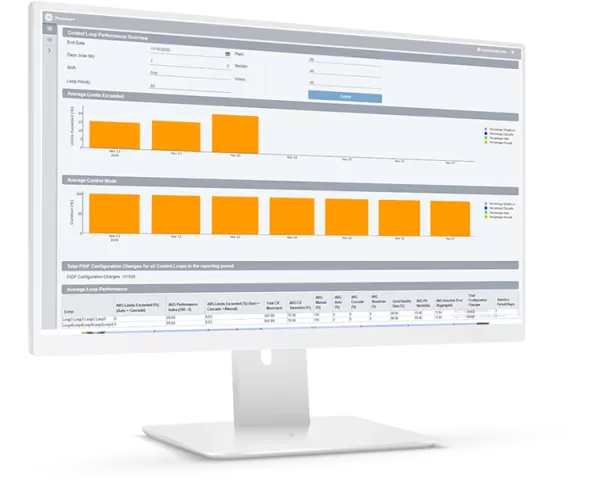

Proficy CSense

Proficy CSense manufacturing analytics software uses AI and machine learning to enable process engineers to mine and analyze data from multiple industrial sources—including people, machines, and processes in a plant. It uses that data to rapidly identify problems, discover root causes, predict future performance, and automate actions to improve quality, utilization, productivity, and delivery of operations.

EXPLORE PROFICY CSENSE